Battery Analytics & Quality Control Platform

Use data to make faster, more informed battery decisions

Stop wrestling with Excel and DIY solutions. Get professional battery analysis, automated quality control, and predictive insights, all from your existing test equipment. Built by battery engineers for battery engineers.

0

% Test Coverage

0

% Prediction Accuracy

0

× Faster Quality Control Decisions

Vibes versus Data: When to rely on intuition and when to rely on data Read the article

Three Ways to Ensure Battery Quality

Incoming Quality Control

For Product Companies

Test and qualify battery cells before pack assembly. Predict performance from supplier formation data and avoid costly field failures.

- Pre-assembly cell screening

- Supplier data integration

- Performance matching for packs

- Warranty risk assessment

Manufacturing Quality Control

For Battery Production Lines

Optimize formation, grading, and EOL testing. Predict final performance during formation to reduce grading time and improve yield.

- Formation process optimization

- AI-powered cell grading

- EOL test automation

- Yield improvement analytics

R&D Test Optimization

For Development Labs

Accelerate battery development from prototype to production. Manage test data across multiple cyclers and predict scale-up challenges early.

- Multi-cycler data integration

- Prototype characterization

- Scale-up risk prediction

- Recipe optimization tools

Measurable Business Impact

Proven ROI that justifies investment and drives competitive advantage

Why Engineering Managers Choose Micantis

See Micantis in Action

Automated Data Management

Seamless data integration from all your test equipment with intelligent processing.

- Automatic uploads from cycle testers and safety equipment

- Metadata extraction links data to cell/pack entities

- Signal extraction processes data automatically on import

- Image classifier associates safety test photos

- Complex reports generated with just clicks

Advanced Analysis Tools

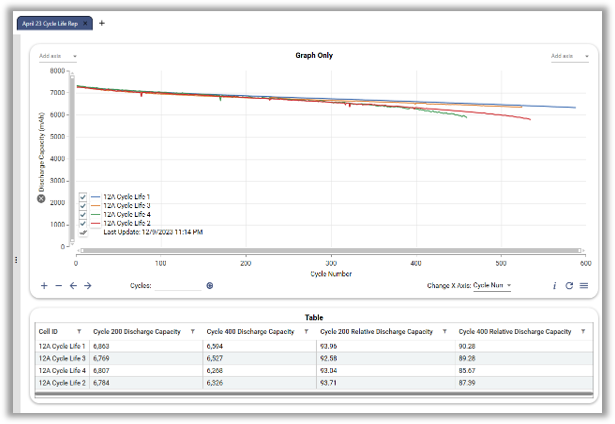

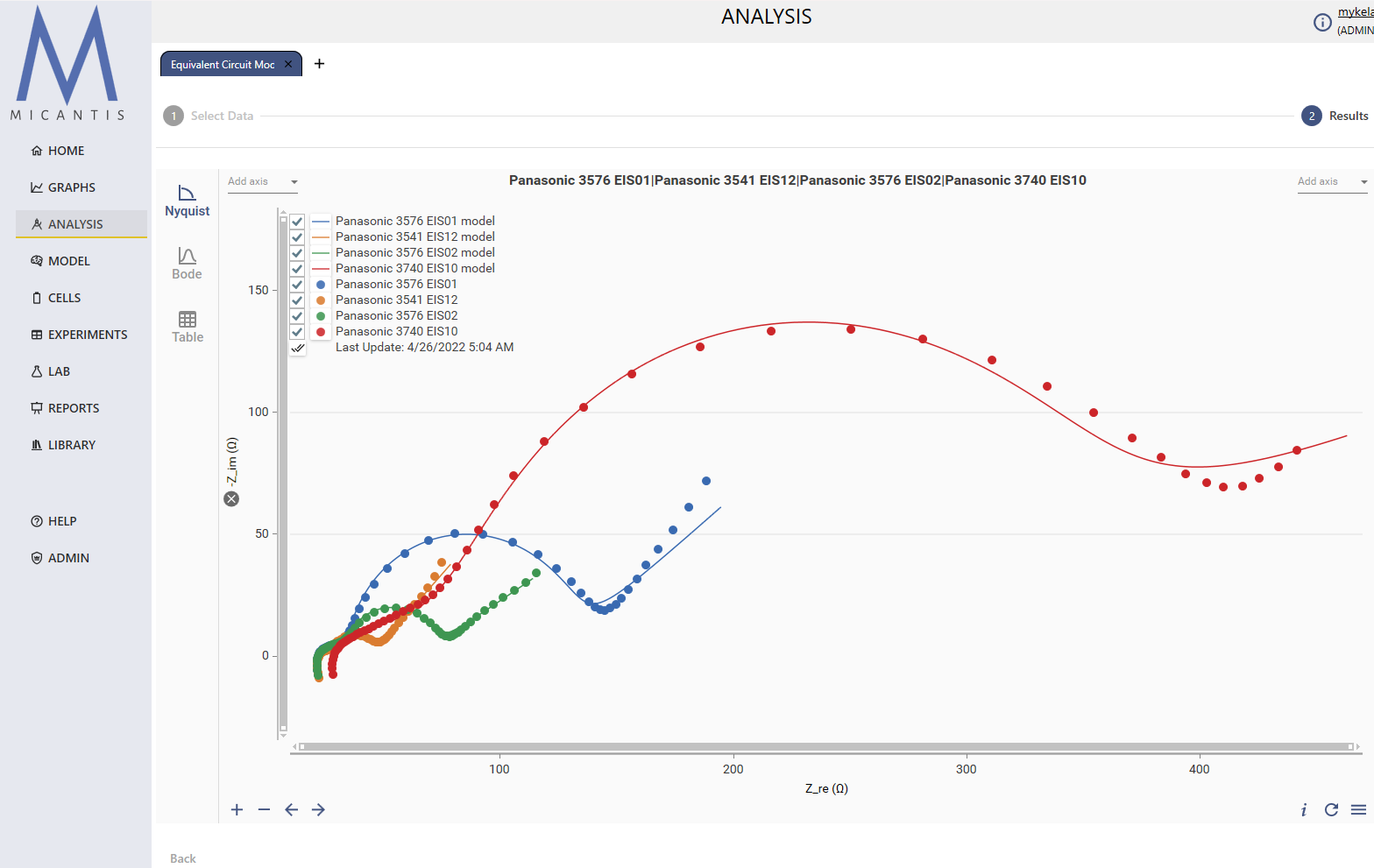

Graphs and analysis tools designed specifically for battery data.

- HPPC, EIS, cycle life analysis

- dQ/dV and DCIR calculations

- Compare cell or process data

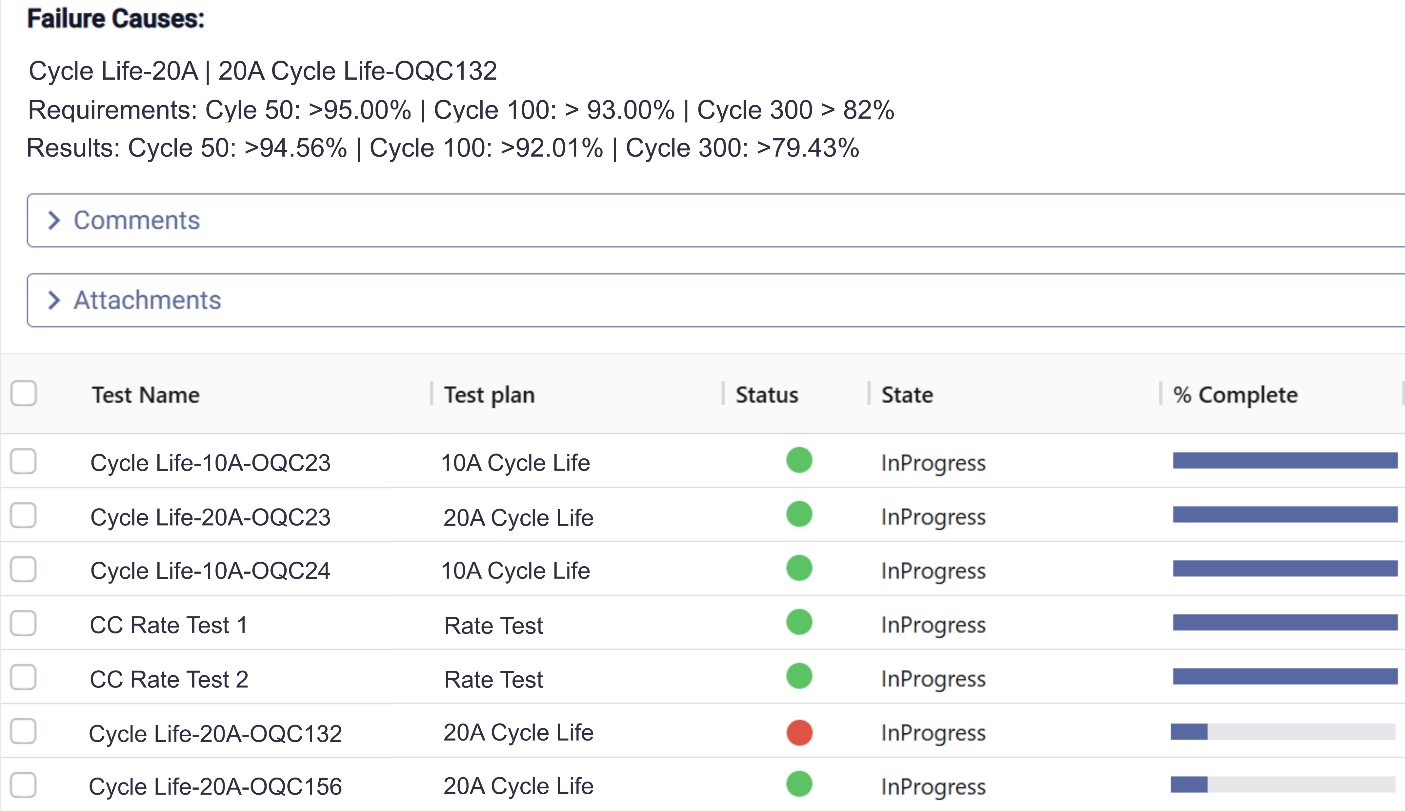

Real-Time Test Management

Near-real-time updates of equipment status and test lab monitoring.

- Equipment status dashboard

- Test progress tracking

- Automated alerts on failures

Discover Everything Micantis Can Do

From automated data import to AI predictions, explore our complete platform capabilities

Explore All FeaturesEnterprise-Grade Platform

Developer APIs & Data Science Tools

Get started in seconds with our Python SDK and Jupyter notebook integration.

pip install micantis- Simple Integration: Import and start analyzing battery data immediately

- Jupyter Native: Works seamlessly in notebooks with built-in visualizations

- Pandas Compatible: Direct DataFrame integration for data science workflows

- Async Support: High-performance async/await for large-scale analysis

- Rich Documentation: Comprehensive guides and examples at pypi.org/project/micantis

import micantis

# Connect and analyze

client = micantis.Client()

cells = client.get_cells(chemistry="NMC")

predictions = client.predict_cycle_life(cells)

# Instant visualization

predictions.plot()Enterprise Resilience & High Availability

Scale confidently with our Enterprise tier featuring Azure's premium infrastructure and disaster recovery capabilities.

- Multi-Zone Redundancy: Deploy across Azure Availability Zones for 99.99% uptime SLA

- Geo-Redundant Storage: Automatic cross-region replication with 16 nines durability

- Premium Database Tier: Azure SQL Database with automatic failover groups and global read replicas

- Enhanced Recovery: Point-in-time restore up to 35 days with cross-region backup

- Global Distribution: Active geo-replication for worldwide low-latency access

- Advanced Protection: DDoS Protection Standard and threat detection

- Dedicated Support: 24/7 monitoring with priority incident response

- Custom SLAs: Tailored service level agreements for your requirements

"The only realistic alternative to navigating terabytes of excel sheet data"

Ready to Accelerate Your Battery Innovation?

Join industry leaders who are already making battery decisions faster with Micantis.

Request Demo Explore Use Cases