Supplier Quality Management

Complete visibility into your battery supply chain quality

Take Control of Your Battery Supply Chain

Managing battery quality from multiple suppliers shouldn't require juggling spreadsheets and manual reports. Micantis provides comprehensive supplier quality management that scales with your operations.

From incoming inspection to long-term performance tracking, get real-time insights into supplier quality trends, automatic compliance documentation, and early warning of potential issues before they impact production.

Your Automated Workflow

Complete automation from receipt to shipment

Your Automated Workflow

Complete automation from receipt to shipment

Incoming Quality Control Features

Comprehensive tools to manage your supplier relationships and ensure quality

Centralized Test Management

Track all supplier testing from one dashboard

Centralized test tracking across all suppliers with automated data collection from incoming inspection stations. Monitor test progress, results, and compliance in real-time.

- Automated data import: Connect to all major cyclers automatically

- Real-time monitoring: Live test status updates and progress tracking

- Custom protocols: Supplier-specific test procedures and requirements

- Historical repository: Complete test data archive with search capabilities

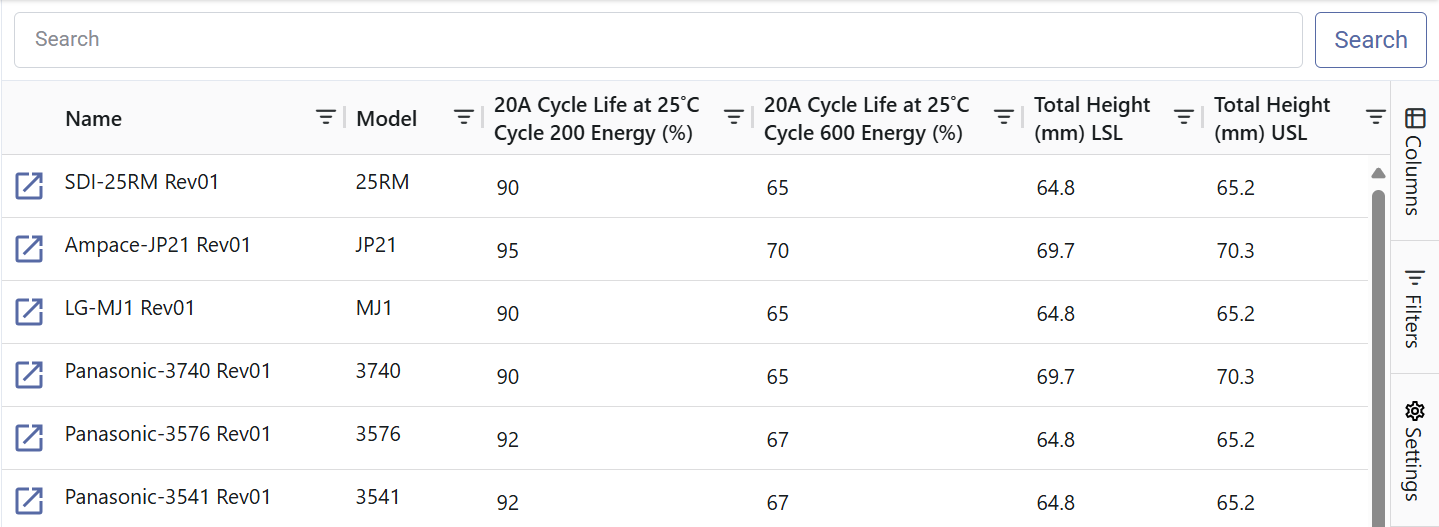

Specifications & Version Control

Never work with outdated specifications

Maintain supplier-specific specifications with full version history. Track changes, compare revisions, and ensure everyone works with the latest requirements.

- Version control: Full history of spec changes with approval workflows

- Supplier-specific: Unique requirements for each supplier relationship

- Change tracking: Complete audit trail of modifications and approvals

- Auto compliance: Automatic checking against current specifications

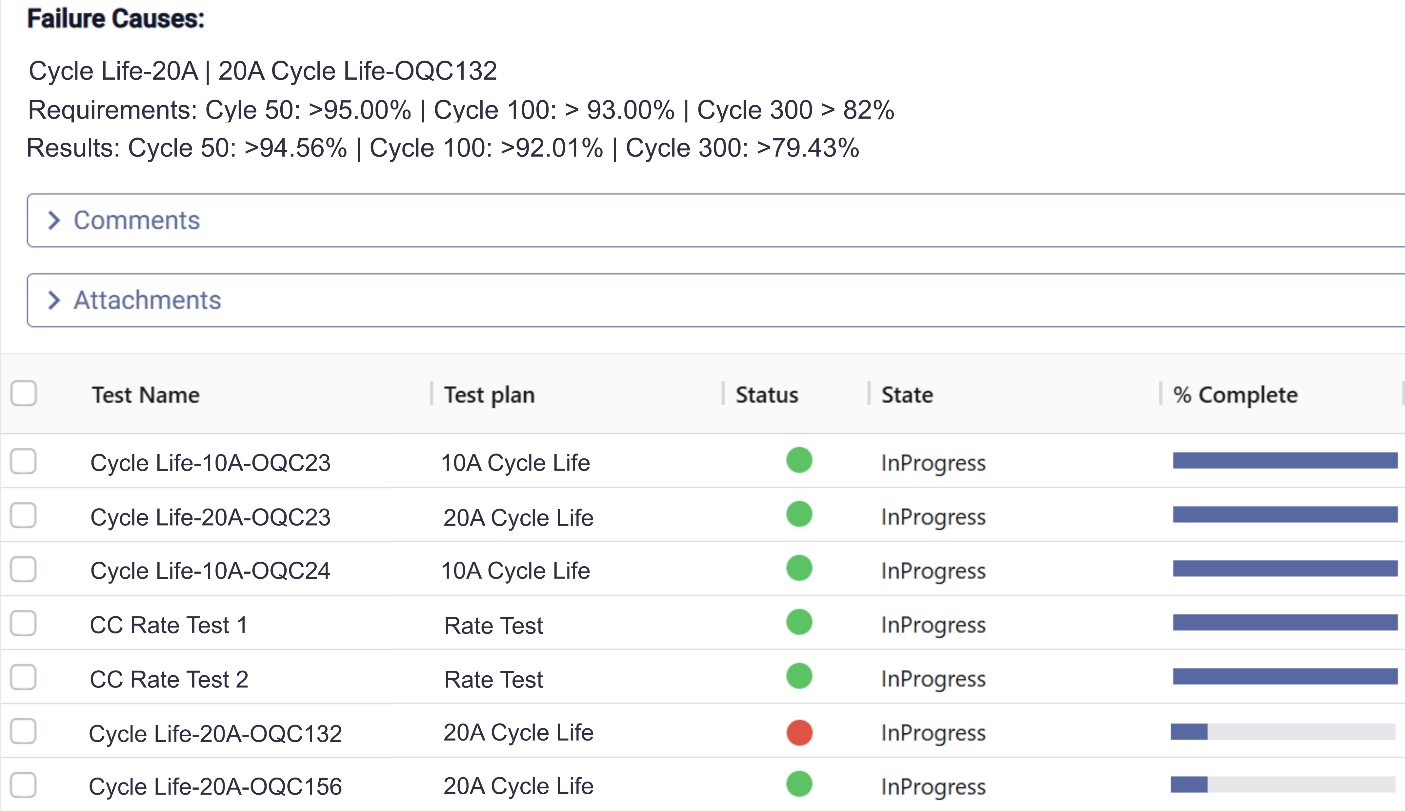

Automatic Failure Notifications

Instant alerts when quality issues arise

Instant alerts when cells fail specifications. Configure multi-level escalation, root cause tracking, and automatic supplier notification workflows.

- Real-time detection: Immediate notification of specification failures

- Custom thresholds: Set alert levels for different failure types

- Multi-channel alerts: Email, SMS, and dashboard notifications

- Escalation workflows: Automatic routing to appropriate personnel

Escalation: 30 min → Production Director

Auto Actions: Hold shipment, Notify supplier

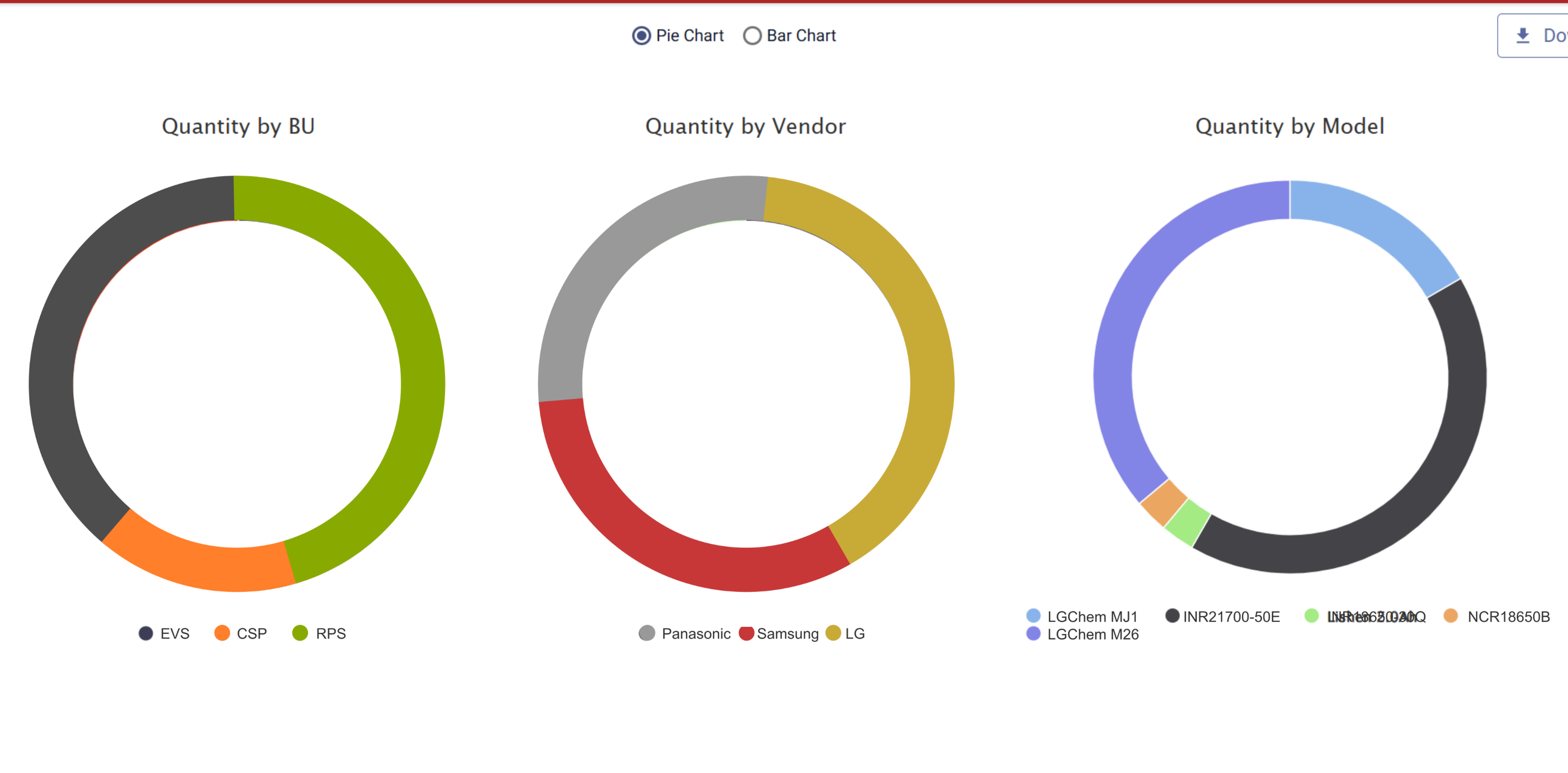

Pass/Fail Trends by Supplier

Data-driven supplier performance insights

Track quality metrics across suppliers with interactive dashboards. Identify trends, compare performance, and make data-driven sourcing decisions.

- Supplier scorecards: Comprehensive rankings and performance metrics

- Trend analysis: Historical performance tracking and forecasting

- Quality comparison: Side-by-side supplier quality metrics

- PPM tracking: Parts-per-million defect rates and yield analysis

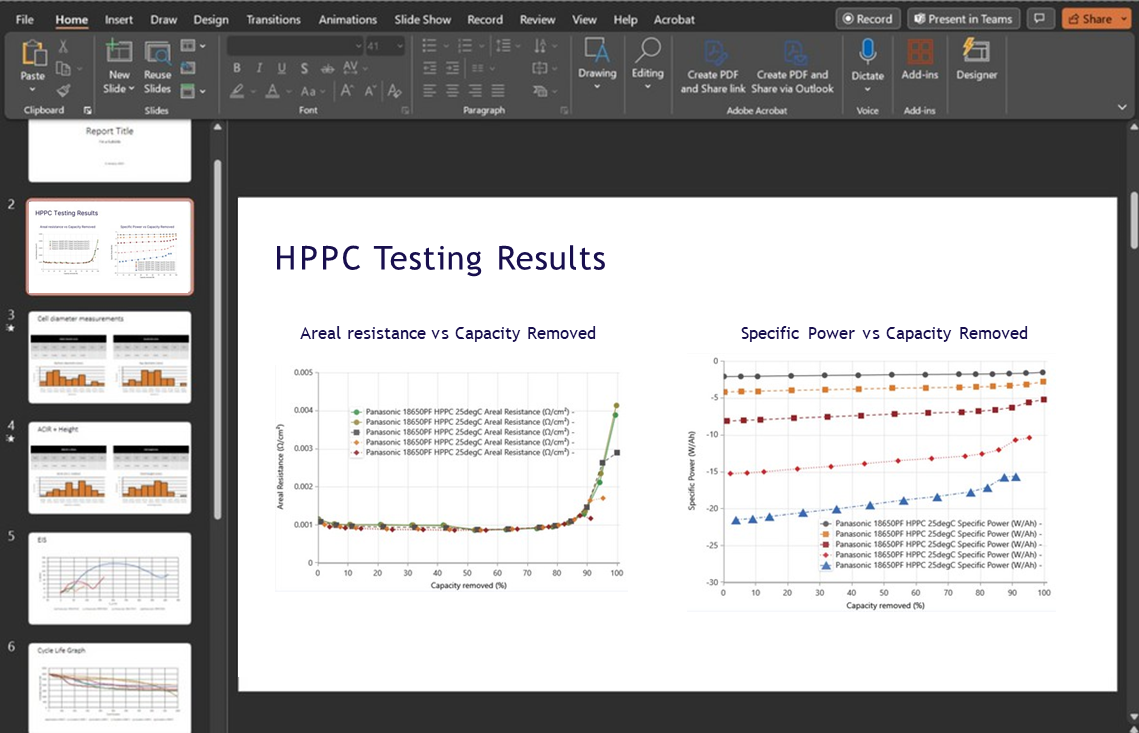

Automatic Report Generation

Professional reports in minutes, not days

Generate comprehensive quality reports automatically. From daily summaries to monthly supplier reviews, get the documentation you need without the manual work.

- Scheduled generation: Automatic report creation on your schedule

- Custom templates: Reports tailored to your specific requirements

- Multi-format export: PDF, Excel, PowerPoint, and web formats

- Distribution lists: Automatic delivery to stakeholders

Complete Batch Traceability

Track every battery from materials to customer

Complete traceability from raw materials through pack assembly. Track batch performance over time and quickly identify affected units in case of issues.

- Full genealogy: Complete material and process history tracking

- Batch analytics: Performance trends and quality metrics by batch

- Warranty correlation: Link field failures to manufacturing batches

- Root cause analysis: Quickly identify source of quality issues

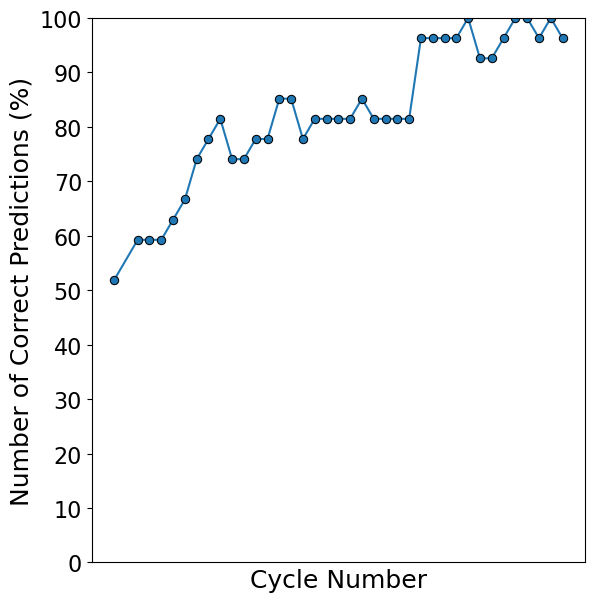

ML Early Detection

Predict long-term performance from initial testing with 99.7% accuracy.

Our machine learning models analyze formation and early cycle data to predict cycle life, enabling you to:

- Reduce testing time by 85% - Know performance after just 50 cycles

- Catch quality issues early - Identify degradation patterns before acceptance

- Optimize inventory - Stock only cells that meet long-term requirements

- Negotiate with confidence - Data-driven supplier discussions

Why Choose Micantis for Supplier Quality?

90% Faster Reporting

What used to take days now takes minutes. Automatic report generation saves your team 20+ hours per week.

Zero Defect Escapes

Multi-layer quality checks and ML predictions ensure no bad cells make it to production.

30% Cost Reduction

Identify best-performing suppliers and reduce warranty claims through better incoming quality control.

Seamless Integration

Works with your existing equipment and systems

Compatible with leading cycler brands:

Plus 50+ other cyclers and test equipment

Ready to Transform Your Supplier Quality Management?

Join leading manufacturers who trust Micantis for battery quality control.

Request Demo Contact Us