Outgoing Quality Assurance

Micantis helps you maintain end-to-end quality control from materials to customer delivery

Complete Manufacturing Quality Assurance

Track every battery from raw materials through production to customer delivery, ensuring each step meets specifications and quality standards.

Micantis provides comprehensive outgoing quality control that connects material development, cell production, testing, and customer delivery into one seamless quality system. Know that every battery you ship will meet or exceed customer expectations.

End-to-End Material Tracking & Quality Verification

Customer specifications verified at every step

Comprehensive Quality Assurance Features

Customer-Specific Test Plans

Tailored quality programs for each customer

Set up repeating test plans with specific specifications for each customer. Define unique test sequences, acceptance criteria, and reporting requirements that automatically execute for each production batch.

- Custom test sequences: Define specific tests for each customer

- Automated scheduling: Tests run automatically per production plan

- Multi-tier specifications: Different limits for different grades

- Application-specific testing: EV, ESS, consumer electronics profiles

- Sampling plans: Statistical sampling per customer requirements

- Repeat testing: Automatic retest scheduling for validation

Example: Customer A Test Plan

Automatic Report Generation

Customer-ready documentation in seconds

Generate comprehensive quality reports automatically for each shipment. Reports include all test results, specifications compliance, statistical analysis, and certificates of conformance in your customer's required format.

- Custom templates: Reports in each customer's required format

- Specification verification: Pass/fail against all criteria

- Statistical analysis: CPK, PPM, distribution charts

- Performance summaries: Key metrics and trends

- Compliance certificates: CoA, CoC generation

- Multi-format export: PDF, Excel, XML for customer systems

Drag-and-drop report builder with real-time visualization and customizable components

Example report automatically generated in Micantis

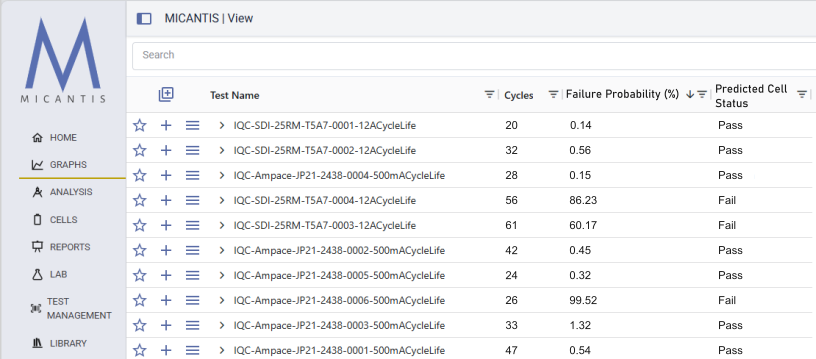

Machine Learning Early Detection

Predict long-term performance before shipping

Our ML models analyze formation and early cycling data to predict cycle life with 99.7% accuracy. Ship with confidence knowing each battery will meet long-term performance requirements.

- Formation analysis: Detect quality issues in first 10 cycles

- Cycle life prediction: 1000+ cycles from 50-100 test cycles

- Grade optimization: Automatically sort cells by predicted performance

- Warranty risk scoring: Identify high-risk cells before shipping

- Process correlation: Link predictions to manufacturing parameters

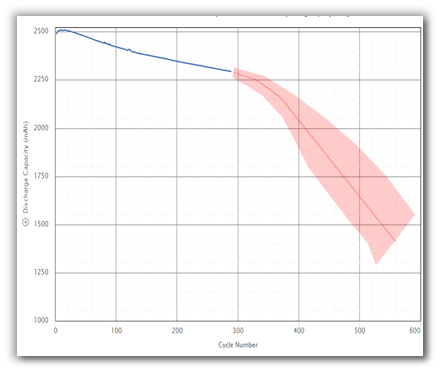

Advanced ML predictions with performance analytics and trend analysis

Predictive modeling with confidence intervals for cycle life forecasting

Process Drift Detection

Proactive quality monitoring with predictive alerts

Monitor production quality trends and catch variations before they impact customers. Our advanced SPC monitoring system tracks all manufacturing parameters in real-time and provides predictive alerts.

- Real-time SPC monitoring: Continuous tracking of all process parameters

- Control charts: Visual monitoring with statistical process control

- Predictive alerts: Early warnings before limits are exceeded

- Equipment correlation: Link performance to specific equipment

- Shift analysis: Track variations by operator and time period

Real-Time Notifications

Instant alerts for rapid response to quality issues

Get immediate notifications when specifications are not met, enabling rapid response and preventing quality issues from reaching customers. Customize alert thresholds and escalation paths for your team.

- Specification violations: Immediate alerts when limits are exceeded

- Process deviations: Notifications for any manufacturing anomalies

- Equipment warnings: Alerts for equipment performance issues

- Customer updates: Notifications when requirements change

- Smart escalation: Automated escalation to appropriate personnel

Benefits of Complete Quality Assurance

Zero Defects

Ship only batteries that meet all customer specifications

75% Less Testing

ML predictions reduce physical testing requirements

10x Faster Reports

Generate compliance documentation in seconds

Customer Trust

Comprehensive documentation builds confidence

Transform Your Outgoing Quality Assurance

Ensure every battery meets customer specifications with complete traceability and automatic documentation.

Get Started Contact Us