The Definitive Guide to Comparing Battery Testing Devices

If you're on the hunt for battery testing devices, you want something fast, reliable, and capable of delivering clear insights into your battery's performance and health. The key to optimizing battery designs and boosting your R&D cycle lies in choosing a testing device that not only meets today's standards but is also equipped to handle the evolving demands of the industry.

The right battery testing device can dramatically reduce development costs, streamline data management, and shorten your time to market. Whether you're designing innovative batteries for electric vehicles or ensuring the quality of batteries for consumer electronics, the ability to rapidly assess and optimize battery designs is crucial.

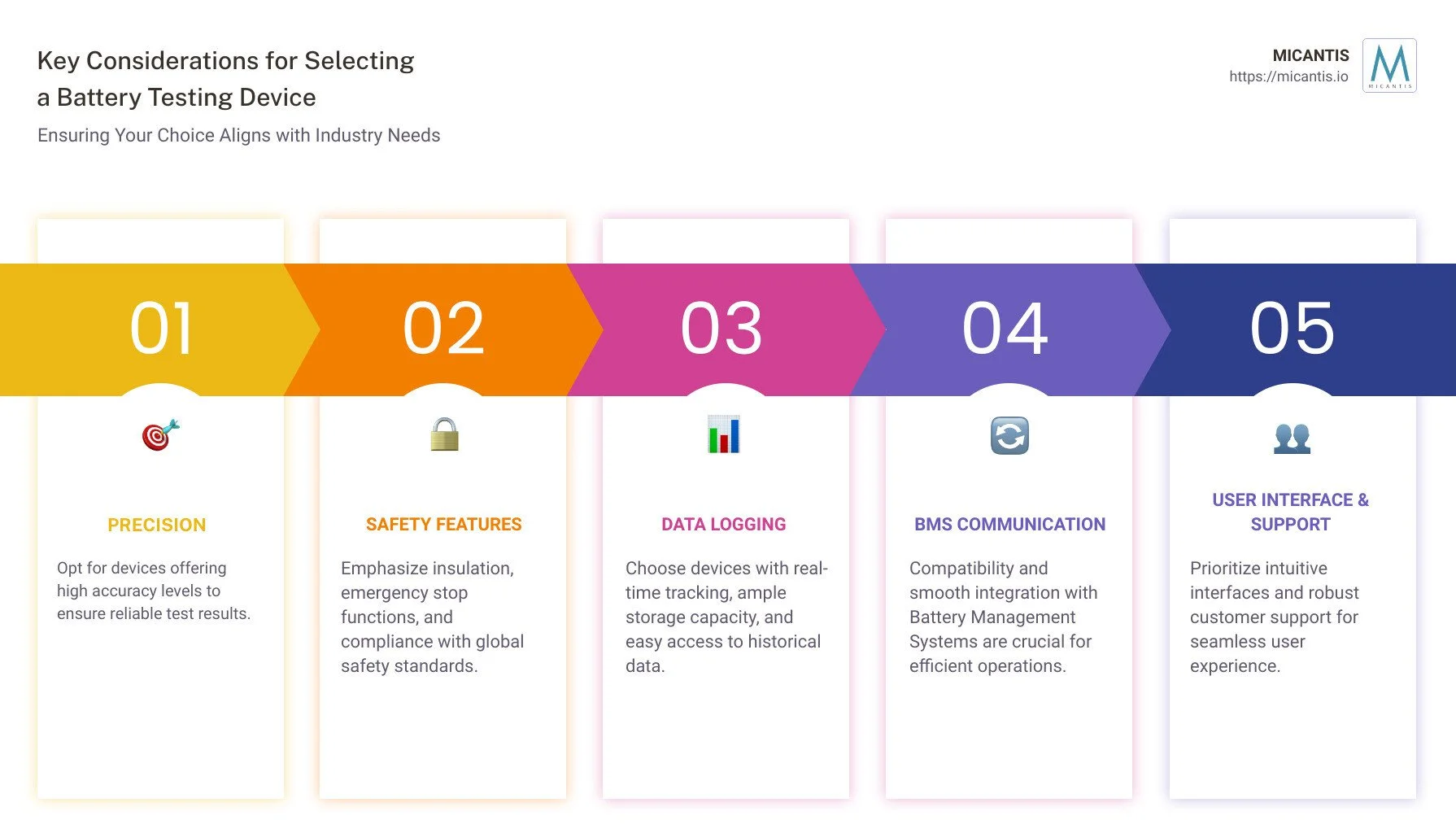

Choosing the right device comes down to a few non-negotiables: precision, safety features, robust data logging, and seamless communication with Battery Management Systems (BMS). It's not just about having a device that can perform standard tests; it's about having a tool that integrates with your workflow, enhances your engineering tasks, and provides actionable data swiftly.

In summary, as you dive into battery testing, your focus should be on finding a device that not only performs basic evaluations but also aids in advancing your product's reliability and efficiency.

Understanding Battery Testing Devices

When we talk about Battery Testing Devices, we're diving into a world where precision meets practicality. These devices are essential tools in ensuring the reliability, efficiency, and longevity of batteries across various applications. Let's break it down into simple terms.

Types of Battery Testing Devices

There are several types of devices used for testing batteries, each serving a unique purpose:

Electronic Testers: These are the go-to for quick and accurate measurements of a battery's performance metrics like voltage, capacity, and resistance.

Hydrometers: Used for lead-acid batteries, they measure the specific gravity of the electrolyte, which tells us about the battery's state of charge.

Multimeters: While not exclusively for batteries, multimeters can measure voltage and, with some additional functions, check battery health.

Load Testers: These apply a load to the battery to simulate real-world usage conditions, helping to evaluate how the battery will perform under stress.

Applications

Battery testing devices find their applications in a wide range of fields:

Automotive: Testing car batteries to ensure they can reliably start the engine and power electronic components.

Renewable Energy Systems: Evaluating storage batteries in solar or wind power systems for efficiency and longevity.

Consumer Electronics: Ensuring that batteries in devices like smartphones, laptops, and cameras meet the required specifications for safety and performance.

Industrial & Backup Systems: Testing batteries that provide emergency power to critical systems in hospitals, data centers, and telecommunications.

Key Features to Look For

When selecting a battery testing device, here are some key features to consider:

Precision and Resolution: The device should provide accurate and detailed readings, allowing you to make informed decisions based on the battery's condition.

Safety Features: Look for devices with built-in safety features to protect both the user and the battery from potential harm during testing.

Data Logging: The ability to log data is invaluable for tracking a battery's performance over time, identifying trends, and predicting future behavior.

BMS Communication: Devices that can communicate with a Battery Management System (BMS) offer advanced insights into the battery's health and operational status.

In the realm of Battery Testing Devices, the importance of choosing the right tool cannot be overstated. Whether you're ensuring the reliability of a car battery, managing a fleet of backup systems, or developing the next generation of consumer electronics, the right testing device is key to success. With a focus on precision, application-specific features, and safety, you can ensure your batteries will meet and exceed expectations.

Remember that the goal is not just to test but to understand and improve. Let's explore how to evaluate battery testing equipment in our next section, keeping these key considerations in mind.

Types of Battery Testing Devices

When it comes to ensuring the health and efficiency of batteries, having the right tools is crucial. Let's dive into the types of battery testing devices you'll encounter: Electronic Testers, Hydrometers, Multimeters, and Load Testers. Each serves a unique purpose in the battery testing process, offering insights into different aspects of battery health and performance.

Electronic Testers

Electronic Testers are the go-to devices for a quick health check of your batteries. They measure parameters like voltage, capacity, and resistance, providing a comprehensive overview of the battery's condition. What makes them stand out is their ability to give immediate feedback, which is essential for maintenance and troubleshooting tasks.

For instance, Arbin Instruments is known for their high-precision electronic testers that cater to both low and high current applications, showcasing the versatility of electronic testers in various settings.

Hydrometers

Moving on to Hydrometers, these devices are all about understanding the specific gravity of the electrolyte in lead-acid batteries. This measurement is a direct indicator of the battery's state of charge. Eagle Eye Power Solutions, for example, offers digital hydrometers that not only measure specific gravity but also temperature, allowing for accurate assessments of battery health.

Multimeters

Multimeters are the Swiss Army knives of electrical testing. They can measure voltage, current, and resistance, making them incredibly versatile. While they may not provide as detailed insights into battery health as dedicated battery testers, their ability to estimate the charge rate makes them invaluable for quick checks and troubleshooting.

Load Testers

Lastly, Load Testers simulate real-world conditions to evaluate a battery's performance under load. This is crucial for understanding how a battery will behave in its operational environment. Load testing can reveal potential issues that might not be apparent under no-load conditions, such as a battery's inability to maintain voltage when powering a device.

Each type of testing device plays a crucial role in battery maintenance and diagnosis. By selecting the appropriate tool for the task at hand, technicians can ensure that batteries are not only functioning as expected but are also optimized for longevity and reliability.

As we've seen, from the precision of electronic testers to the practical insights offered by hydrometers and multimeters, and the real-world relevance of load testers, there's a tool for every aspect of battery testing. With the right equipment, predicting and preventing battery failures becomes a more manageable task, ensuring that critical systems remain operational when needed the most.

In the next section, we'll delve into how to evaluate these battery testing devices, focusing on aspects such as hardware, software, data management, and support. This will guide you in choosing the right equipment to meet your specific needs.

Key Factors to Consider

Choosing the right battery testing devices involves considering several critical factors. Let's break these down into simple terms to help you make an informed decision.

Precision and Resolution

Precision is all about how consistently a battery testing device can give you the same result under the same conditions. Imagine you're measuring the length of a table multiple times; if you get the same number every time, your tape measure is precise.

Resolution refers to the smallest change a device can detect. Think of it as the number of decimal places on your digital watch. More decimal places mean you can tell the time more precisely, down to the second or even smaller.

For battery testing, high precision and resolution mean you can trust the test results to make crucial decisions about your batteries.

Safety Features

When dealing with batteries, safety cannot be overstated. Batteries store a lot of energy, and if something goes wrong, it can lead to dangerous situations. Look for devices that have built-in safety features like:

Overvoltage protection to prevent damage from charging a battery too much.

Short circuit protection to avoid sparks or fires if wires touch when they shouldn't.

Temperature monitoring to keep an eye on the battery's heat, as high temperatures can be a sign of trouble.

Data Logging

Data logging is like keeping a health diary for your battery. It means recording how the battery performs over time. This is crucial because it can help you spot problems before they become serious. For example, if you notice the battery's capacity is slowly dropping, it might be time for a check-up or replacement. Look for devices that make data logging easy and intuitive.

BMS Communication

A Battery Management System (BMS) is like the brain of a battery pack. It manages how the battery charges and discharges, keeps it within safe operating conditions, and much more. When choosing battery testing devices, ensure they can communicate effectively with the BMS. This communication is key to getting accurate insights into the battery's health and performance.

In summary, when evaluating battery testing devices, focus on precision and resolution for trustworthy measurements, prioritize safety features to protect both the user and the battery, ensure robust data logging capabilities for tracking battery health over time, and check for compatibility with BMS communication for a comprehensive understanding of battery performance. By keeping these factors in mind, you'll be well on your way to selecting the right equipment for your needs.

In the next section, we'll explore popular battery testing methodologies to further guide your choice of the appropriate testing equipment.

Popular Battery Testing Methodologies

When it comes to ensuring the health and efficiency of batteries, knowing the right testing methodologies is key. Let's dive into some of the most widely used techniques in the industry: Impedance Testing, Discharge Testing, and Ground Fault Tracing.

Impedance Testing

Impedance Testing is like giving your battery a quick health check without needing to shut it down. It's an online test, meaning it can be done while the battery is in use. This method measures the opposition (impedance) a battery has to an alternating current. Why does this matter? Higher impedance can indicate problems like aging or deterioration within the battery.

Quick and non-intrusive: This testing can be performed frequently.

Identifies weak cells early: It helps in spotting potential failures before they occur.

This method is particularly useful for maintenance teams looking to keep systems running without interruption.

Discharge Testing

Next up is Discharge Testing. Think of it as a fire drill for your battery system. This offline test simulates an actual power outage by putting the battery through a real-world scenario where it has to supply power. By measuring how well the battery performs under these conditions, you get a clear picture of its health and capacity.

Real-world simulation: It shows what happens if the battery needs to take on the full load.

Comprehensive assessment: It tests the battery's actual output under load conditions.

Although more time-consuming and requiring the system to be taken offline, discharge testing gives you invaluable insights into your battery's true capabilities.

Ground Fault Tracing

Finally, we have Ground Fault Tracing. Batteries in complex systems are often 'floating', meaning they're not directly connected to the ground but may still develop ground faults. Such faults can be tricky to find but are crucial for safety and system integrity.

Safety first: Identifies potentially hazardous faults.

Saves time: Allows quick pinpointing of issues in complex systems.

The Battery Ground Fault Tracer is a specialized tool that makes this detective work much easier, allowing for precise identification and resolution of these faults.

In conclusion, selecting the right battery testing methodology depends on your specific needs—whether it's for routine maintenance, a comprehensive health check, or safety inspections. By incorporating these techniques into your battery management strategy, you ensure not just the longevity of your batteries but also the reliability and safety of your entire system.

In the next section, we'll guide you on how to evaluate battery testing equipment to match these methodologies, ensuring you have the right tools for the job.

How to Evaluate Battery Testing Equipment

Choosing the right battery testing equipment is crucial for ensuring the reliability and longevity of your batteries. Here’s a simple guide to help you evaluate the options:

Hardware

The physical build and specifications of the device matter. Look for:

Durability: Can it withstand the environment it will be used in?

Precision: Does it offer the accuracy needed for your specific battery types?

Connectivity: Can it interface with other systems or devices for enhanced functionality?

Software

Software plays a key role in how effectively you can use the device. Consider:

Ease of Use: Is the interface intuitive? Can your team use it without extensive training?

Features: Does it offer the functionalities you need, such as programmable test sequences or automatic data logging?

Updates: How often is the software updated, and how easy is it to install these updates?

Data Management

The ability to store, analyze, and manage data efficiently is vital. Look for:

Logging Capabilities: Can the device log data at the frequency you need?

Analysis Tools: Are there built-in tools to help you analyze the data, or will you need external software?

Data Export: How easily can you export data for further analysis or reporting?

Auxiliary Features and Accessories

Consider what additional features or accessories could enhance testing. This might include:

Temperature Measurement: Can it measure and log temperature, a critical factor in battery performance?

Protective Cases: Are there protective cases available to transport the device safely?

Adapters and Connectors: Does it come with or support various adapters and connectors for different battery types?

Support

After-sales support is just as important as the product features. Evaluate:

Warranty: What kind of warranty is offered, and what does it cover?

Technical Support: Is there accessible technical support to help troubleshoot issues?

Calibration and Maintenance: How easy is it to get the device calibrated or serviced?

When evaluating battery testing equipment, remember to consider not just the immediate needs but also future requirements as your battery testing demands evolve. By carefully assessing hardware, software, data management capabilities, auxiliary features, and the level of support provided, you can select a device that will serve your needs well into the future.

In the next section, we'll answer some frequently asked questions about battery testing devices, helping you further in making an informed decision.

Frequently Asked Questions about Battery Testing Devices

When it comes to maintaining and ensuring the efficiency of batteries, whether for industrial use, vehicles, or portable electronics, having the right battery testing devices is crucial. Here are some of the most common questions along with straightforward answers to help you navigate battery testing devices.

What equipment is used to test a battery?

Electronic Testers are widely used for a quick and accurate assessment of a battery's health. They measure parameters like voltage, current, and resistance, providing insights into the battery's performance and potential issues.

Hydrometers are another essential tool, especially for lead-acid batteries. They measure the specific gravity of the electrolyte, which can tell you a lot about the state of charge and health of the battery.

Which device is used to check battery?

For a more general check, Multimeters are versatile devices that can measure voltage, current, and resistance. They are useful for a quick snapshot of battery health and are a must-have tool for any technician's toolkit.

Hydrometers, as mentioned, are specifically used for checking the electrolyte levels in lead-acid batteries, making them an indispensable tool for this type of battery.

What is the best tool to test a car battery?

Load Testers apply a load to the battery and measure its ability to maintain voltage. They are an excellent way to simulate real-world conditions and assess how a car battery will perform under stress.

CCA Analyzers measure the Cold Cranking Amps, which is crucial for understanding how well a car battery can start an engine in cold conditions. This is particularly important for ensuring that your vehicle is reliable in all weather conditions.

By understanding the various tools available for testing batteries and their specific applications, you can ensure that you're equipped to maintain and verify the health of batteries across a wide range of uses. Whether it's a car battery, industrial battery, or a small electronic device, choosing the right testing equipment is a step towards efficiency and reliability.

Conclusion

In batteries, whether they power our cars, our homes, or our devices, ensuring their reliability and longevity is not just a matter of convenience—it's a necessity. The importance of regular testing cannot be overstated. It's the difference between being stranded on the roadside or ensuring your critical systems stay up when the power goes out. That's where the right battery testing devices come into play, and why Micantis stands out in this essential field.

Importance of Regular Testing

Regular testing of batteries isn't just about preventing failure; it's about optimizing performance and extending the life of your batteries. By identifying potential issues early through methods like impedance testing and discharge testing, you can take corrective actions before these problems escalate into costly failures. This not only saves money in the long run but also ensures the reliability of systems that we often take for granted until they stop working.

Moreover, with the advent of sophisticated battery technologies and the increasing reliance on renewable energy sources, the complexity of battery systems is at an all-time high. This complexity demands equally sophisticated testing and monitoring solutions. Regular testing allows us to understand the health and performance of these systems in real-time, ensuring that they operate at their peak efficiency.

Micantis

At Micantis, we understand the critical role that batteries play in our modern world. That's why we've dedicated ourselves to providing state-of-the-art battery testing devices that not only meet but exceed the demands of today's battery technologies. Our devices are designed with precision, ease of use, and comprehensive data management in mind, ensuring that you have all the tools you need to monitor and maintain your batteries effectively.

Our commitment to innovation is evident in every product we offer. From our advanced hardware that delivers unparalleled accuracy, to our intuitive software that simplifies data analysis, Micantis is at the forefront of battery testing technology. We believe that by empowering our customers with the right tools, we can make a significant impact on the efficiency and reliability of battery-powered systems across the globe.

In conclusion, the importance of regular battery testing cannot be understated, and choosing the right testing devices is crucial. Micantis stands ready to be your partner in this journey, offering advanced solutions that ensure your batteries are not just tested, but truly understood. Trust in Micantis to keep your world powered, reliably and efficiently.