Optimal DOE Methods

Optimal Design of Experiments (DOE) maximizes knowledge produced for a given number of tests. A design of experiment is simply a table of values where each column corresponds to a control variable, and each row corresponds to a cell design that will be built and tested in the experiment. Each element in the table indicates the value of the corresponding variable (column) for the corresponding design (row).

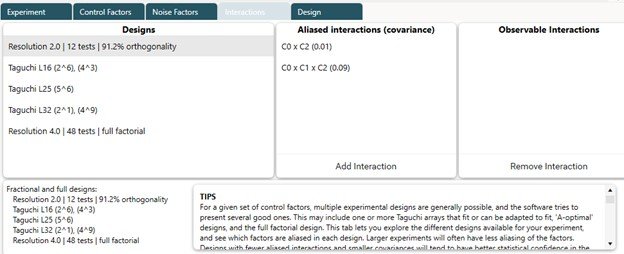

The term “resolution” refers to the level of variable interactions that can be resolved. More precisely, it is the minimum number of variables that are aliased. For example, take a design of experiments with four control variables C0, C1, C2, and C3. A resolution 4 design would only alias the combination of all four variables. So C0 itself is aliased with no two-way interactions—it is only aliased with the three-way interaction between C1, C2, and C3 (“C1xC2xC3”). Higher-level interactions like this are less common and we can often ignore them as a first guess. The interactions C0xC1 and C2xC3 would also be aliased, along with all such permutations involving all four variables.

A resolution 3 design might only require half as many rows, and it would have one or more groups of three variables aliased – perhaps C0, C1, and C2 are aliased, for example. Statistically, that means we can’t tell the difference between an effect of C0 and an effect of C1xC2. The same is true for C1 versus C0xC2 and for C2 versus C0xC1. In exchange for this aliasing, the resolution 3 DOE has fewer rows, and so fewer cells we need to build and test. Resolution 3 designs are great for making a first pass at several factors – we can always test more cells later to resolve these interactions if needed.

For a given set of control variables (i.e. electrolyte choice, additive quantity, etc.), there are many tools and methods to build an optimal DOE including looking up tables, Minitab, JMP, Excel macros, and others. A/B tests, where only a single parameter is varied, don’t need a DOE, and produce less useful information than an optimal DOE. Full factorial designs are a related kind of DOE that are easy to compute and often a waste of resources

Micantis and Optimal Design of Experiments

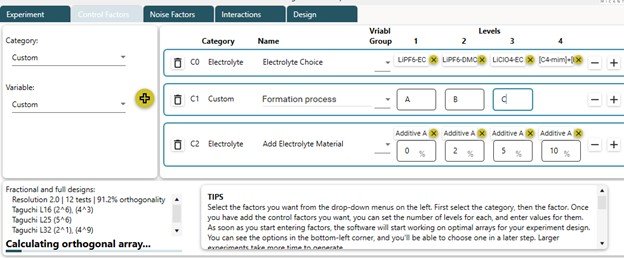

The Micantis platform uses several algorithms to produce optimal DOEs specifically for the variables you specify. These include lookup and fitting of precomputed arrays, generated regular orthogonal designs, optimal nonregular orthogonal designs, and J-optimal nearly orthogonal arrays. Several algorithms go into these designs, and you can choose the most appropriate DOE for your application.

In the first part of the design of experiments engine, appropriate DOEs are pulled from a library of standard orthogonal arrays including Taguchi arrays. Usually, most precomputed arrays will not fit a given set of control variables exactly. Extra columns are removed, table entries are re-coded, and columns are re-ordered to match your specific variables. The result may not be optimal, depending on how much the precomputed design needs to be adjusted to fit the variables. These DOEs are very fast to compute and appear instantly as you build your experiment in Micantis WorkBook.

The Micantis Design of Experiments Engine then computes regular generated designs. These are computed by first generating a full factorial design for a subset of the variables. The engine then generates columns corresponding to the remaining variables by multiplying the columns of the full factorial subset design together. This has the effect of intentionally aliasing interactions with variables to include more variables in a smaller number of rows. The engine runs through all the permutations of subsets and generates combinations to find the best designs. This is more compute-intensive than fitting the precomputed arrays but is still fast to calculate.

The final engine step is the most complex and time-consuming. The algorithm starts with a random matrix with the columns corresponding to control variables and then uses an exchange algorithm to improve the condition of the matrix (J-optimality) until convergence criteria are satisfied. This is repeated for many different random designs. The whole process is then repeated for different lengths of tables (row count) determined by the specific variables and levels.

For the shortest (fewest rows) tables, the designs are J-optimal and non-orthogonal. This means that some variables are directly aliased with other variables. On the other hand, these non-orthogonal designs require very few cells. It’s possible start by running a non-orthogonal array, and then later add more cells to the experiment to increase the resolution to 3 or higher.

For longer lengths of tables, the exchange algorithm often finds the shortest possible resolution 3 design. This can be particularly valuable for non-standard DOEs, like one with a mix of variables with 3, 4, or even 5 levels. For the longer length tables, the algorithm can take some time. These designs will appear in the experiment table in the WorkBook experiment builder as they are calculated.

References

Montgomery, D. C. (2017). Design and analysis of experiments. John Wiley & Sons.

NIST/SEMATECH e-Handbook of Statistical Methods, http://www.itl.nist.gov/div898/handbook/, 2020.

Xu, H., Phoa, F. K., & Wong, W. K. (2009). Recent developments in nonregular fractional factorial designs. Statistics Surveys, 3, 18-46.